Melting and Casting of Magnesium Alloys

|

The research effort is focused on the development of melt treatment and casting technologies, such as melt purification & refinement, semi-continuous ingot casting of wrought Mg alloys, die-casting, squeeze casting, twin-roll strip casting and scrap on-site recycling. Breakthroughs have been made in die-casting and squeeze casting techniques, which have been used for mass production of Mg components for automobile, motorcycle and hand tools. Furthermore, vertical twin-roll strip casting technique was first used to produce AZ31B magnesium strips, and a newly developed magnesium scrap on-site recycling system has been employed in die-casting industry.

|

|

|

|

|

Schematic show of the working principle of a newly developed squeeze casting technique

|

|

|

|

|

Die-castings of automobile components

|

semi-continuous cast ingots of Mg alloys

|

|

|

|

Microstructure of Mg alloys formed at different cooling condition

|

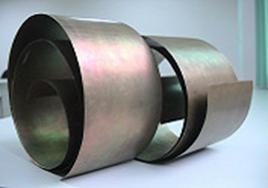

Thin sheet coils rolled from horizontal continuous twin-roller cast strip

|